Training

We offer a wide variety of on-site training and can quickly costumize any training to fit your needs.

TRAINING

Employees are better equipped to recognize and mitigate potential hazards, lowering the likelihood of accidents and injuries. This proactive approach to safety contributes to a safer workplace. A more productive workforce is one that is safe and healthy. When employees feel safe in their workplace, they can concentrate on their tasks without being distracted by safety concerns, resulting in increased productivity.

PROFESSIONAL CREDENTIALS:

- Authorized OSHA Outreach Instructor, 10- & 30-hr. (Trainer ID No. 0917002)

- Certified Safety Professional (Certificate No. 20305)

- Certified Professional Ergonomist (Certificate No. 1617)

- American Red Cross Instructor/Authorized Provider (ID #104366)

- Certified Industrial Hygienist (Certificate No. CP 10353)

OSHA Construction Outreach (10-Hour & 30-Hour)

Hazardous Waste Operations and Emergency Response (HAZWOPER)

DOT HAZMAT

Crane Safety

Electrical/Arc Flash Safety (NFPA 70E)

Defensive Driving & Fleet Safety

Competent Person for Scaffolding and for Trenching & Excavation

Forklift Safety & Operator Certification

NEED A MOCK OSHA INSPECTION? MAYBE A SAFETY AUDIT?

TRAINING

Training is an essential part of risk management. Your company can reduce the likelihood of workplace incidents and the associated financial and reputational consequences by identifying and addressing potential risks. All employees must be equipped with the knowledge and skills needed to protect themselves and their colleagues from workplace hazards. This improves their overall well-being and fosters a caring culture within the organization.

TOOLBOX TALKS/TAILGATE SAFETY MEETINGS

Toolbox talks are conducted regularly, often daily or weekly, to ensure that safety is consistently prioritized. This frequent engagement helps keep safety at the forefront of employees’ minds.

LOCK-OUT/TAG-OUT (LO/TO)

Is a safety procedure used in a variety of industries to ensure that dangerous machines and equipment are properly shut down and do not restart accidentally during maintenance or servicing. The LO/TO process uses locks and tags to isolate energy sources, preventing the release of hazardous energy that could injure workers.

CONFINED SPACE ENTRY AND RESCUE

Confined space entry and rescue training is crucial for ensuring the safety of workers who may need to enter confined spaces in the course of their duties. This training provides individuals with the knowledge and skills needed to identify, assess, and mitigate the risks associated with confined spaces, as well as respond effectively in the event of an emergency.

FALL PROTECTION & FALL PREVENTION

Fall protection and fall prevention training are critical for creating a safe working environment and lowering the risk of falls-related injuries. Employers should tailor training to their specific workplace needs and ensure that employees are competent in the use of fall protection measures.

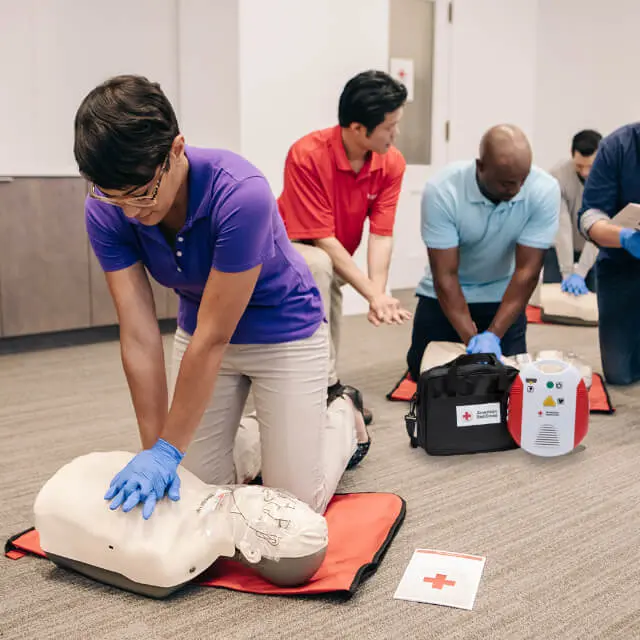

CPR/AED AND FIRST AID

Individuals must be trained in CPR/AED and First Aid in order to respond confidently and effectively in emergency situations. This training contributes to safer environments and increases the likelihood of a positive outcome in medical emergencies. It is recommended that these life-saving skills be updated and refreshed on a regular basis.